-40%

(pack) Rod packing K01 ID8mm-50mm (choose dimensions) NBR/cottonfabric+NBR/POM

$ 2.86

- Description

- Size Guide

Description

Welcome to our oil seal store. Huge amount of different dimensions and materials are on stock!! Don´t hasitate to contact us. We also have o-ring store, bearing store,chain store,hydraulic and pneumatic seals store, belt store, etc - we can send together.

Most of oil seals are on stock, so we are usually shipping within 2 bussiness days.

Longer handling time 10-20 days occures just on sold out items.

We can also use UPS express shipping. Shipping rates are: UPS to USA

30USD,

UPS to Europe, U.K, Germany, France

20USD,

UPS to N.a S.America, Canada, Mexico, Brazil, Asia, China, Japan, Australia

50USD

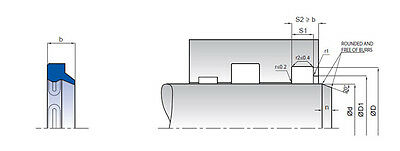

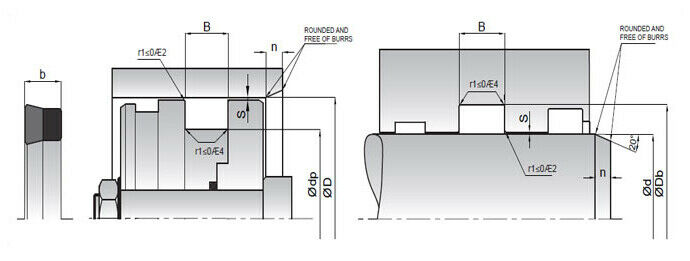

K01 is a seven piece single acting sealing set which consists of one reinforced cotton fabric backup ring , one thermoplastic header ring , three reinforced cotton fabric middle rings , and two elastomeric nitrile rubber middle rings.

PRODUCT ADVANTAGES

• Adjustable seal housing height due to the reason of being usedin open grooves.

• Functions even with poor surfaces

• Robust seal

• Easy installation and removal

• Long service life

• Able to work until the maintenance of continuity systemsbecause of the adjustable housing

• Very good sealing performance both in high and low pressures

APPLICATION

Used especially in hard working conditions such as iron and steel industry , mining equipment , marine hydraulics , scrap cutters and special cylinders where the actual conditions are difficult to predict.

MATERIAL

CODE

NBR

80 SHORE A

NB9001

COTTON FABRIC NBR

FB8001

POM

PM9903

OPERATING CONDITIONS

MEDIA

Mineral oils(DIN 51524)

HFA and HFB

HFC

TEMPERATURE

-30°C +105°C

+5°C +60°C

-30°C +60°C

PRESSURE

≤400 Bar

≤400 Bar

≤400 Bar

SPEED

≤0.5 m/sn

≤0.5 m/sn

≤0.5 m/sn

Note: The above data are maximum values and cannot be used at the same time.

SURFACE ROUGHNESS

Ra

Rmax

Sliding Surface Ød

≤0.4 μm

≤3.2 μm

Groove Base ØD

≤1.6 μm

≤6.3 μm

Groove Flanks B

≤3.2 μm

≤16 μm

Note: It is recommended to have 50% to 90% of the working surface material contact area value.

INSTALLATION

Being assembled in adjustable housing , the groove housing should have an adjustability of 7.5% of the seal height. If there is a requirement of being used in closed housings , individual parts should be cut with 45° angle and staggered by 75° angle at installation. When strongly squeezed , the flexibility of the sealing set may be substantially reduced. This could cause excessive friction force , high wear and vibrated operating under low pressures. It is very important that the assembly tools must be of soft material and have no sharp edges. Before installation all individual parts of the seal must be oiled with system oil.

NOTES

For special applications that require high temperatures , our seal set is being manufactured in the following configuration , reinforced cotton fabric with FKM for header and middle rings and special mixture of PTFE backup ring. Permissible sealing gap S value should not be above 0.15 mm. For inner diameters above 200 mm , all the middle rings are being produced from reinforced cotton fabric with NBR material. Additional middle rings can be used depending on the application.